The recent publication is in line with a political accord worldwide: "With the Sustainable Development Goals (SDGs) of the 2030 Agenda, the member states of the United Nations reached agreement for the first time on global sustainability goals and the principles laid out in the Agenda. The 17 SDGs and their corresponding 169 sub-goals apply equally to developing, newly industrialized and developed countries."

Why is this relevant to the SG Group now?

First, we added "sustainable" to the SG core values reliable, entrepreneurial, inventive in the brand manual and the Code of Conduct of the SG Group. Second, all OEM's started to tighten their acceptance rules for their supplier selections. According to the OEM's rules, suppliers need to show their commitment to sustainability in the context of production, materials, and logistics. Such requirement was especially highlighted amid the recent VW Fast program events. Suppliers who will not commit to adapt to their sustainable Code and don't show proof of the implementation of measurements accordingly will be waived from the bidding list and are not admitted as a supplier any longer.

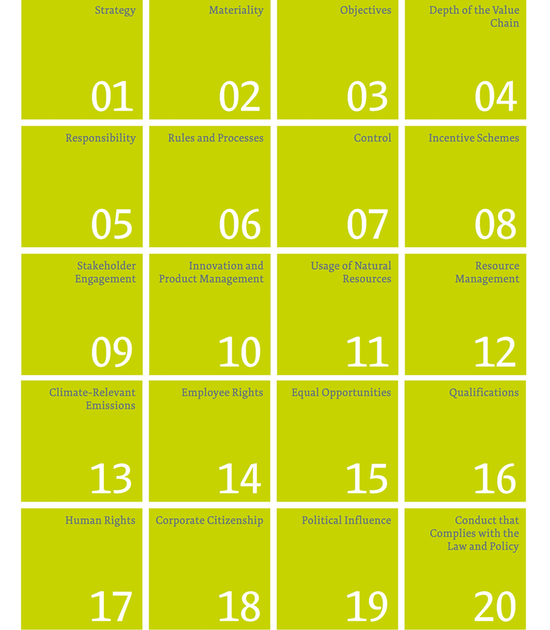

Official sustainability reporting

An advantage of participating in conforming to implementing sustainability goals in the company is that sustainability reporting to the public is made possible via government platforms. Such reporting supports, among other things, also the visibility of a company over time through the publicly accessible Code database. Published reports are comparable on a like for like basis with one another. Use of the Code is free of charge. The Sustainability Code Office and the Code training partners and mentors provide reporting assistance. Get familiar with the German Sustainability Guidelines and as well with the UN guidelines by clicking the link to their English website. It is a handy source for orientation and inspiration.

Continuous improvements

SaarGummi Group's plant in Wadern-Büschfeld, Germany, bolsters its improvement engagements with a Best Business Practice example that fits right into the sustainability context:

"Non-destructive measurement of paint parts." Reduction for test time from 10 min to 1 min without destroying parts proves efficiency.

The following success stories show SG DEBF's continuous push ahead to become a leading supplier in an increasingly demanding environment:

- DAF/Paccars „10ppm and better“ Award.

- WKW 95,7% Audit – “best quality supplier”

- Mayser 93,5% Audit – “A – supplier”

- Best apprentice in Saarland for “Process mechanic plastic and rubber”

- The project “Development of a robot-based winding system for primary and secondary door seal” was done with a generous funding by the European Union and the State of Saarland.

SG corporate communication: newsroom at saargummi.com

Copy: Matthias Held, mapmovingstory GmbH

Visual: Holodyne Systems GbR

Table: Sustainability Code

Photos: Dawin Meckel, Ostkreuz