In this context, the publication of the information paper "World Robotics R&D Programs" by the International Federation of Robotics (IFR) on the worldwide research and development programs in the field of robotics is particularly topical and relevant.

The paper makes clear that new technologies, such as artificial intelligence, Big Data and 5G, are driving government funding in Asia, Europe and America. It further highlights the objectives of officially driven governmental research funding programs and what we can learn from these findings.

"Each country has its own characteristics of robot programs based on its specific background and history," says Prof. Dr. Jong-Oh Park, Vice Chairman of the IFR Research Committee and member of the Executive Committee. "As a result, we see that robotics programs established by the most advanced robotics countries have a very different strategic focus".

Here are a few summaries from that report:

Example China

The strategic plan "Made in China 2025" names advanced robots among the top ten core industries. The development plan for the robotics industry already dynamically sets out the goals for China in 2020, which include

- The development of three to five globally competitive robot manufacturers,

- The creation of eight to ten industrial clusters,

- Achieving 45 percent of the domestic market share for China's high-end robots and

- The increase of the robot density in China to 100 robots per 10,000 workers

IFR's statistical yearbook "World Robotics" shows that in 2018 China will have reached a robot density of 140 units per 10,000 workers in the manufacturing industry. In 2019, the Chinese government invested 577 million dollars in the development of intelligent robots.Example Japan

According to IFR's statistical yearbook "World Robotics", Japan is the world's number one industrial robot manufacturer, supplying 52 percent of global deliveries in 2018.

The robot strategy in Japan is a key policy of the "Abenomics" growth strategy. The robot-related budget for 2019 has been increased to 351 million dollars, with the goal of making Japan the world's center of robot innovation. The action plan covers both the manufacturing industry and important service sectors such as healthcare, agriculture and infrastructure.Example Korea

The "Intelligent Robot Development and Supply Promotion Act of Korea" urges to develop the robot industry in Korea as a core industry in the fourth industrial revolution. The 3rd Basic Intelligent Robot Plan, published in 2019, promotes the systematic selection and concentration of promising public and private sectors. Key areas of focus are: manufacturing companies, selected areas of service robots (including healthcare and logistics), next-generation key components and key robot software.

The robot-related budget for 2020 is 126 million dollars (151 billion won). The statistical yearbook "World Robotics" shows a new record of around 300,000 operational industrial robots in the Republic of Korea for 2018 (up ten percent). Within five years, the country has doubled the number of industrial robots in operation. In 2018, the country will rank third after Japan and China.Example EU

The robotics projects funded by Horizon 2020, the European Union's 8th Framework Programme, represent a wide range of research and innovation topics - from manufacturing, commercial and healthcare applications to consumer, transportation and food robotics. Through this program, the European Commission is providing an estimated $780 million in funding for research and innovation in robotics over its seven-year period.

The main themes of the 2018-2020 work program are the digitization of industry through robotics, robotic applications in promising new areas and core robotics technologies such as AI and cognition, cognitive mechatronics, human-robot interaction and model-based design and configuration tools, with a total budget of $173 million.Example Germany

As part of its High-Tech Strategy, Germany supports the use of new digital technologies in business and administration. The "PAiCE" program, with a funding budget of 55 million dollars (50 million euros) over five years, focuses on the development of digital industrial platforms and on cooperation between companies that use these platforms.

The robot-oriented projects focus in particular on the creation of platforms for service robotics solutions in the various relevant application areas such as service, logistics and manufacturing. Germany is the fifth largest robot market in the world and number one in Europe, followed by Italy and France. In 2018, the number of robots sold rose by 26 percent to almost 27,000 units - a new all-time record.Example USA

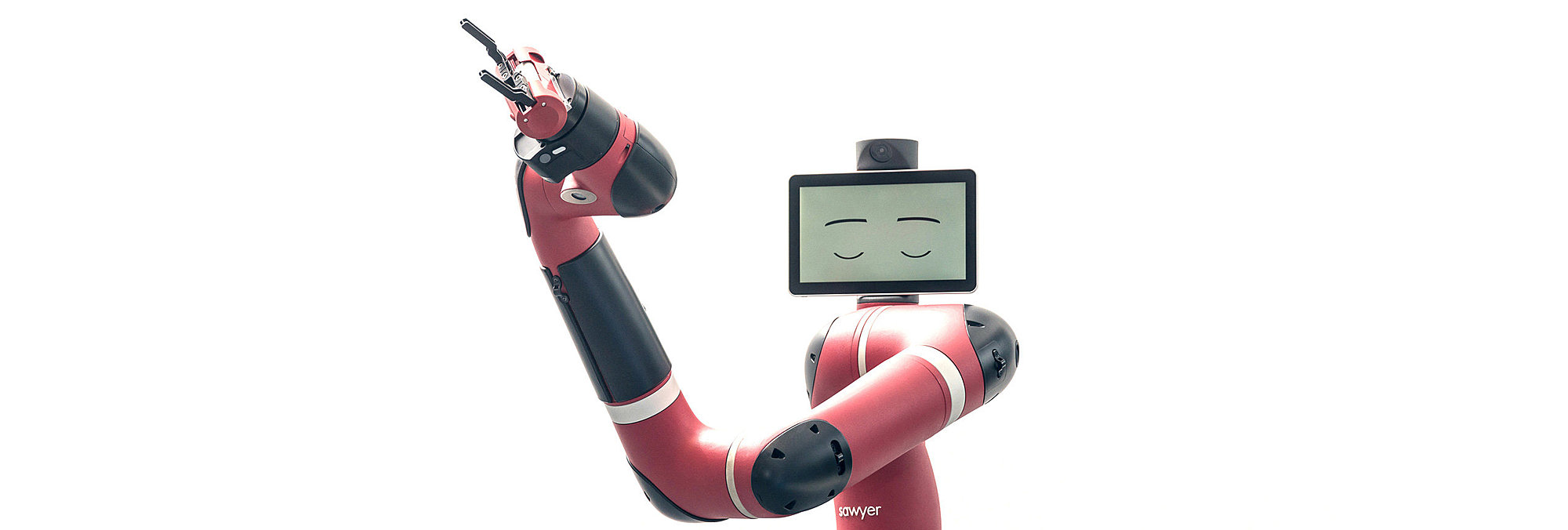

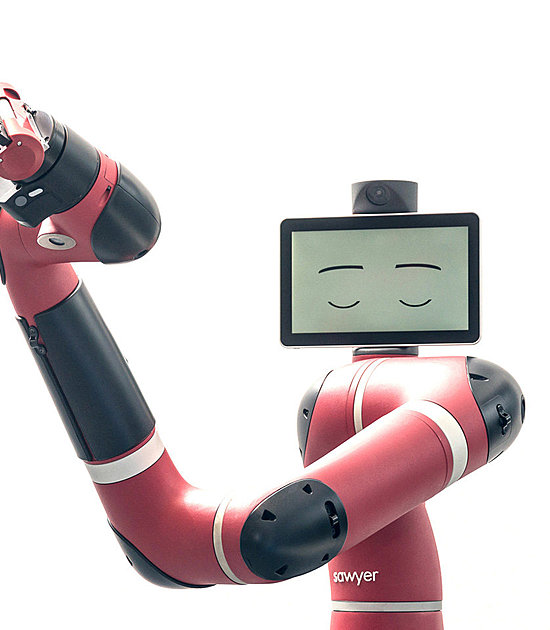

The National Robotics Initiative (NRI) in the USA was created with the support of the US government for basic robotics R&D. Its main objectives focus on the basic science, technologies and integrated systems needed to realize the vision of ubiquitous collaborative robots that support humans in every aspect of life. The focus is therefore on collaborative robots.

In addition, NRI-2.0 promotes collaboration between academia, industry, non-profit and other organizations. The NRI budget for 2019 is $35 million. Additional funding for robotics for defense and space applications is provided by the Department of Defense (DoD) and the Mars Exploration Program.

According to IFR statistics, robotic installations in the United States have risen for the eighth consecutive year, reaching a new high in 2018. In terms of annual installations, the country has taken third place from the Republic of Korea.

Example Robots and Corona Virus

In the fight against the corona virus, speed and strength of cooperation are required. Senova, a Thuringian medtech company and leading developer and manufacturer of rapid test systems for marking biomarkers, viruses and microorganisms, relies on the expertise of Omron's robotics experts for its sought-after rapid corona tests. Together with Kraus Maschinenbau GmbH, Senova and Omron have in recent weeks developed and built special machines that speed up and improve the previously very time-consuming manual production of the tests many times over.

Forced by the current development, Senova has succeeded in bringing the first corona antibody rapid tester to market in record time. These tests, which look similar to a pregnancy test in appearance, are manufactured using the eCobra600 robots. Due to increased production volumes, Omron has now delivered two more eCobra600 Pros and integrated them into the production line. The control and drive systems for the cutting and packaging machine are also made by Omron, developed and built by Kraus Maschinenbau GmbH. The first machine was delivered in mid May 2020. Further lines are in planning due to the huge demand.

The new machine can cut and pack 30 to 45 corona quick tests per minute. Since the demand is so great, capacities are now to be increased rapidly with further machines. Currently, the machines run six days a week from 7 a.m. to 10 p.m.